OUR SERVICES

Zeal with it’s team of experienced technicians aims to offer the optimum to its customers.

WHY CHOOSE US?

Zeal gears pvt limited is a company that is solely dedicated to the production of the high quality gears with high torque performance and can be used to fulfill many industrial requirements.

Over time we have gained expertise in the production of high quality products that aimed at providing a better user experience. We have now multiple ranges of products manufactured by the aced engineers like extruder helical gearbox, parallel shift gearbox, helical gear and pinion, loose gears, crane duty gearbox, helical gearbox of crane and many more such products which would be shortly described later in our products column. Check that out to know more about our services.

Meanwhile, let’s take you through the evolutionary journey of production of these products manufactured in our company.

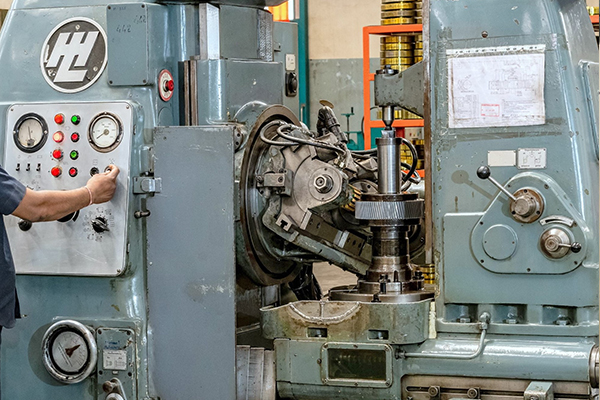

TECHNICIANS

INHOUSE FACILITY

INSTALLATIONS

CITIES

Features of Our Products

Quality

Well, the product quality of our products is something we don’t compromise with. Well, the first thing that satisfies customers before buying any automobile product is to know if the industry is following proper sets of guidelines set by ISO. So, yes, we follow the guidelines and implement them in our manufacturing process and run our products through repeated quality checks.

So, rest assured we don’t compromise with the quality of our products that we manufacture with the full efforts of our engineers and the workers.

Design of Our Products

Our engineers are constantly putting their efforts to manufacture the products that suit your requirements. We employ highly skilled computers and technologies for the preparations of the complete designs of the gears.

Control Systems

Machinery tends to heat over a span of continuous work due to repeated torque and friction which is being exerted on the system. So, this rapid heating of the machinery can slow down the working efficiency of the product. So, to neglect or eliminate that issue we incorporate our machinery with the cooling coils or rods that eventually send the rise in machinery temperature and maintain a relatively cooler temperature to bring out the homeostasis of the machinery.

Gear Body

Now, it is important to know the components or types of raw materials used in the manufacturing procedures. So, we employ material which has high heat transfer capabilities. So, we cast our gearboxes in the Gery cast iron.

And inner walls of the box of the gears are usually coated with high performance oils to reduce the chances of excessive friction and to reduce heating problems.

And a heat resistant coating is also done to improve the efficiency of the machinery to the optimal levels.

Bearings

We use the bearing of supreme quality materials. They are selected by use of the required calculations related to the axial and rotational loads of the gearboxes to design more symmetrical and efficient designs.

Products manufactured by our company

Now that we have introduced you to the inner workings of the company and the raw materials used by our company in the production of the gearboxes. Let’s go through the list of products that are manufactured by our industry.

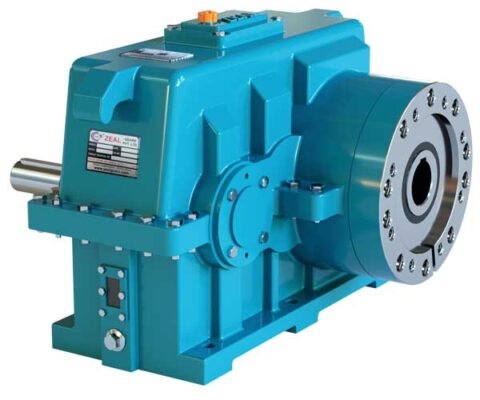

Extruder Helical Gearbox

We manufacture both single shaft and double shaft helical gearbox for extruder with the dimensions set by our engineers that are specifically designed to suit the requirements of the client or industrial requirements.

They have an inbuilt thrust block which makes it highly suitable to be mounted on the spherical rolling bearings.

Not only this, we also manufacture single screw and double screw extruder gearbox.

Helical gears and pinions

We manufacture spiral teeth, helical gears and pinions that work efficiently and produce fewer vibrations and noise.

Other lists of the products that are manufactured by our industry are as follows :

- Loose gears

- Crane duty helical gears.

- Helical gearbox for crane

- Hdpe Extruder GearBox

- Helical gearbox for plastic industry

- Helical gearbox for the rubber industry

- Industrial gearbox

- Gearbox for plastic machinery

- For the food industry

- Customized helical gearboxes( for suiting the specific requirements of certain industries( as asked by the client)