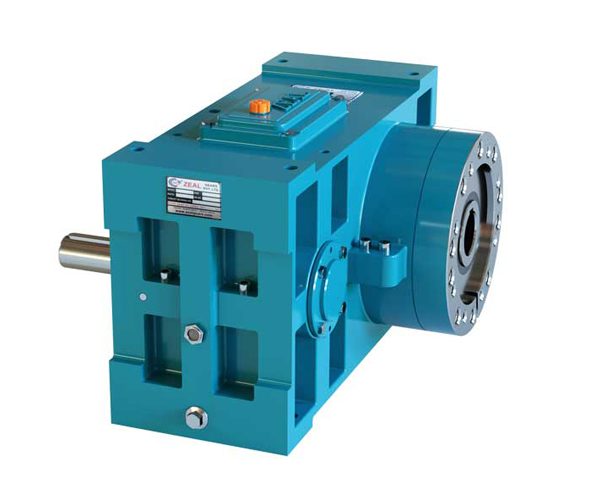

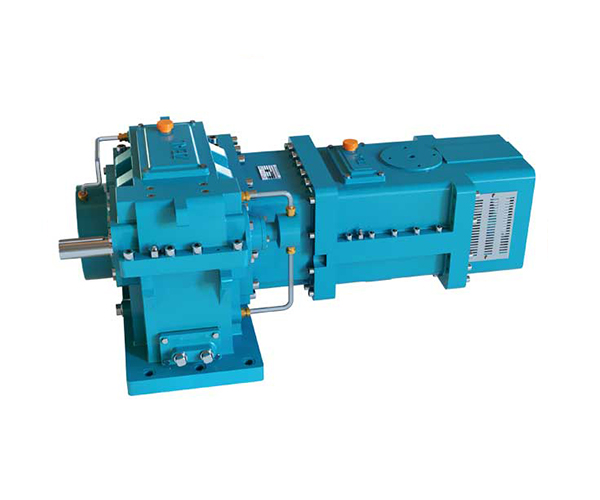

We basically specialize in the production of gearboxes specialized for plastic and rubber extrusion machinery.

A decade of experience has bought nothing but an educational experience for all of our team. As a team, we have evolved over time in every concern whether related to machinery designing or implementing the high technological advancements in our manufacturing procedures.

Our engineers have the innovation to life by putting their consistent and tenacious efforts in designing machinery that is highly efficient and eliminates all the drawbacks which are usually faced while operating machinery. We have basically worked on the following aspects which we can say that differentiates us from other industrial setups:

- We use raw material that is highly efficient and suitable to work according to the kinetics of the machinery.

- It is highly lubricated so it eliminates the risk of development of excessive friction in the machinery.

- Raw materials are selected in such a way that helps with the heat transfer procedure.

- To eliminate the excessive heating procedures cooling wires or rods made up of copper are utilized in the machinery.

- Surface of the gearboxes are smooth so that they glide over each other smoothly.

- They are coated with high performance oils and heat resistant coating materials to increase the overall efficiency of the material

- We select the dimensions of the gearboxes depending upon the requirements and specifications of the needs of the industrial.

So, Zeal Gears Pvt Ltd has covered almost every aspect to eliminate any loopholes of the machinery working. We have designed our machinery in such a way that it works efficiently without interfering with the kinetics of any procedure.

For example, we would be discussing this shortly in our services section as well but to give you a little jest let’s try and understand an example.

So, we manufacture several gearboxes that are supplied to many industries so our aim is to design machinery that fulfills the requirement of every industrial procedure. Now, if we are supplying our gearboxes to any biotechnological industrial setup so, we design our gears accordingly because in that case we can’t afford our machinery to get overheated rapidly as it would disrupt the kinetics of the procedure as the biotechnological procedures are largely based on physiological factors which is temperature, pH and dissolved oxygen.

So, we try to be as specific with our designs as we can be.