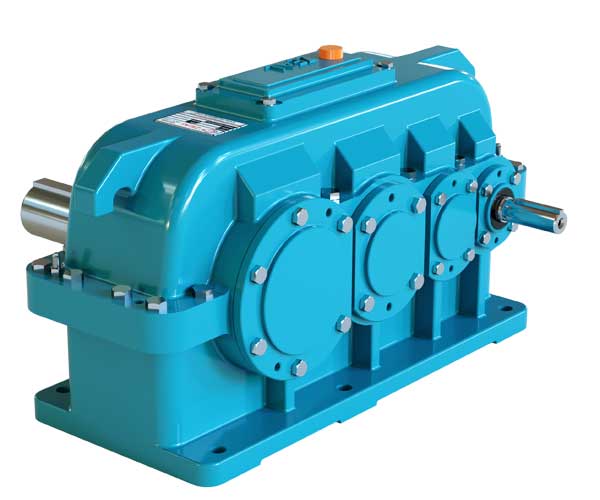

Crane duty helical gearboxes are manufactured to provide the sturdy and efficient gearboxes that can provide the maximal work efficiency on performing heavy duty industrial-scale applications.

At Zeal Gears Pvt Ltd our engineers understand the specifications of each of the machinery and try to manufacture the gearboxes that can be used in conjunction with each of this machinery meanwhile fulfilling the specifications of the kinetics of that industrial process.

Different orientation in which helical gearboxes for cranes are available:

- Vertical

- Horizontal