What is a Helical Gearbox?

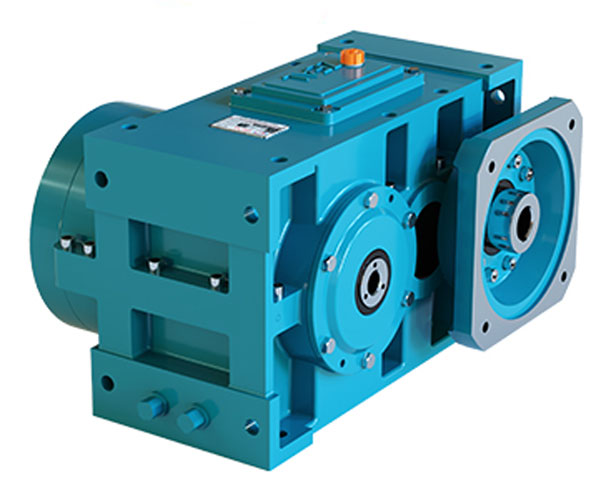

A Helical Gearbox is a type of mechanical gear system designed with angled teeth to provide smooth and efficient power transmission between parallel or non-parallel shafts. The helical design allows for quieter operation and higher load capacity compared to other types of gears.

What is meant by ‘Universal Mounting’ in a Helical Gearbox?

Universal mounting means that the gearbox can be mounted in various orientations and configurations. This flexibility allows it to be used in a wide range of applications and systems, ensuring versatility and ease of installation.

What is an Input Flange, and why is it important?

An input flange is a critical component that connects the gearbox to the driving motor or other input mechanisms. It ensures proper alignment and secure attachment, facilitating the transmission of power from the motor to the gears within the gearbox.

What are the typical applications of a Helical Gearbox with Universal Mounting?

These gearboxes are commonly used in industries such as material handling, conveyors, mixers, crushers, and various other machinery where high torque and efficiency are required.

What materials are used in the construction of the Helical Gearbox?

The gearbox typically consists of high-quality steel for gears and shafts, with the housing made from robust cast iron or aluminum. The choice of materials ensures durability, high performance, and resistance to wear and tear.

How do I select the right Helical Gearbox for my application?

Selection depends on several factors, including the required torque, speed, load capacity, mounting configuration, and environmental conditions. It’s important to consult with a gearbox manufacturer or specialist to determine the best specifications for your specific application.

What are the maintenance requirements for a Helical Gearbox?

Regular maintenance includes checking for proper lubrication, inspecting for wear or damage, and ensuring that all mounting and connection points are secure. Following the manufacturer’s maintenance guidelines can significantly extend the gearbox’s lifespan.

Can this gearbox be customized for specific needs?

Yes, many manufacturers offer customization options, including different input flange sizes, housing materials, and gear ratios, to meet specific operational requirements.

What are the advantages of using a Helical Gearbox with Universal Mounting?

The primary advantages include its high efficiency, low noise operation, versatility in mounting options, and the ability to handle high loads with minimal vibration and wear.

How does the input flange contribute to the performance of the Helical Gearbox?

The input flange ensures that the motor or other input device is securely and accurately connected to the gearbox, which is crucial for efficient power transmission and overall system reliability.

Are there any specific installation guidelines for this type of gearbox?

Yes, installation should follow the manufacturer’s instructions, which typically include proper alignment, secure mounting, correct lubrication, and ensuring that the gearbox is free from any external stresses that could affect performance.

What is the expected lifespan of a Helical Gearbox?

The lifespan varies depending on usage, maintenance, and operating conditions but can range from several years to decades with proper care and routine maintenance.