What is a single-stage helical gearbox?

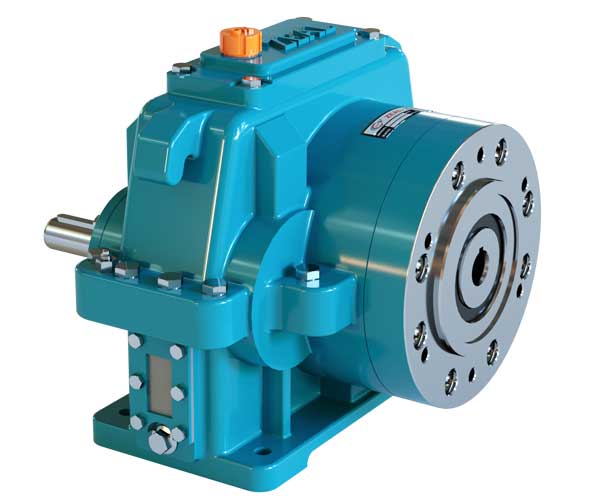

A single-stage helical gearbox is a type of gear reducer that uses a single set of helical gears to transmit power and reduce speed from an input shaft to an output shaft. It provides a fixed reduction ratio in a single stage of gear reduction.

What are the advantages of a single-stage helical gearbox?

Compact Design: Generally smaller and lighter than multi-stage gearboxes.

Smooth Operation: Helical gears offer quieter and smoother operation compared to spur gears.

Efficiency: Provides efficient power transmission with reduced energy loss.

Simple Configuration: Fewer components and simpler design compared to multi-stage gearboxes.

How does a helical gearbox work?

In a helical gearbox, gears with teeth cut at an angle engage with each other in a smooth, gradual manner. This angle of engagement allows for quieter operation and better load distribution, which reduces the overall stress on the gearbox.

What factors should I consider when selecting a single-stage helical gearbox?

Torque and Load: Ensure the gearbox can handle the required torque and load.

Speed Ratio: Match the gearbox’s speed reduction ratio with your application’s needs.

Mounting Type: Choose a gearbox with an appropriate mounting configuration for your setup.

Efficiency: Look for a gearbox that provides the efficiency required for your application.

Environment: Consider factors like temperature, dust, and moisture in the operating environment.

What maintenance is required for a single-stage helical gearbox?

Regular Inspections: Check for signs of wear, leaks, and unusual noises.

Lubrication: Ensure the gearbox is adequately lubricated as per the manufacturer’s recommendations.

Cleaning: Keep the gearbox and its surroundings clean to avoid contamination.

Alignment Checks: Verify proper alignment between the gearbox and the connected equipment.

What are common issues with single-stage helical gearboxes and how can they be resolved?

Noise: Can be caused by misalignment, lack of lubrication, or gear wear. Check alignment, ensure proper lubrication, and inspect gears.

Overheating: Often due to insufficient lubrication or excessive load. Check lubrication levels and ensure the gearbox is operating within its load limits.

Vibration: May indicate misalignment or imbalance. Ensure proper alignment and secure mounting.

What materials are used in single-stage helical gearboxes?

Typically, helical gearboxes are made from high-strength steel for the gears and cast iron or aluminum for the housing. The choice of materials depends on the required load capacity, durability, and operating environment.

Can a single-stage helical gearbox be customized?

Yes, many manufacturers offer customization options for gear ratios, mounting configurations, and materials to meet specific application needs.

How is a single-stage helical gearbox installed?

Alignment: Ensure the gearbox is correctly aligned with the input and output shafts.

Mounting: Securely mount the gearbox to prevent movement or vibration.

Lubrication: Apply the recommended lubricant and verify proper levels.

Connections: Properly connect the input and output shafts to ensure smooth operation.

Where can I obtain replacement parts or service for a single-stage helical gearbox?

Contact the manufacturer or authorized distributors for replacement parts and service. Specialized repair services are also available from third-party providers for maintenance and repairs.