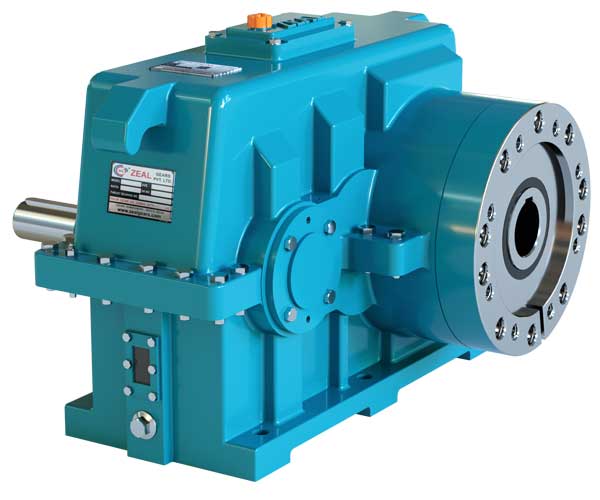

Zeal Gears Pvt. Ltd. offers the best quality Two Stage Helical Gear Box with Oil Pump that is widely used for power transmission in various industries.

Helical Gear Box Two Stage

We have already discussed the helical gearbox one stage. And from our discussion, we know by now that they are highly efficient gearboxes to work with. Then, why do we need an addition to the family of helical gearboxes? Or, why specifically the requirement of the helical gearboxes two stage?

The answer is quite simple. Their need arises because of the following factors:

- They provide a two stage gear reduction performance between the output and the input shaft.

- And second they are required for power transmission purposes.

So, in industrial applications where heavy-duty work is required it becomes the more appropriate choice. We manufacture and supply a wide range of helical gear two stage with unmatched quality.

Design of helical gearbox two stage

Now, designing one stage helical gearboxes are quite simpler processes. But as we proceed towards multistage gearboxes the design becomes more complex. Their designs are usually very large and are highly constrained.

What makes it more complex?

Well, the fact that we would be using different subsets and obviously there would be some kind of interaction between those subsets. That makes the whole designing procedure a Whole lot more tedious if you ask me.

Now, the choice of gear width and the centre distance that you keep between the different subsets is going to influence the gear reduction capacity of helical gearboxes greatly.

So, our engineers optimize the dimensions of the subsets of the gearboxes in such as way that it provides you with maximum gear reduction and high power transmission capacity. Thus, making your procedure a whole lot more efficient.

They have a compressive range of constraints groups utilized in the designing process. Till date at least 24 constraints groups have been studied and implicated in the designing of two stage helical gearboxes.

Now, the basic function of these constraints groups is to minimize the overall volume and second to minimize as much power loss as they can.

Basic design

The basic design of the helical gearbox two stage remains the same as the one stage helical gearboxes.

In essence, they are cast in the same grained iron or steel alloys with anticorrosive metals added to it. And their interior is coated with the coat of anticorrosive paint, high-performance oil and heat-resistant materials.

They have proper lubrication are sealed at the junctions to prevent any oil spillage. They are as efficient as helical gearboxes can be with high power transmission capacity, torque and heat transmission capacity.

Technical Spacification

| Size | Thrust Brg. No. | STD Ratio |

|---|---|---|

| 80D | 32310 | 15 : 1/12.5:1 |

| 95D | 29412 | 12.5 : 1/16 : 1 |

| 110D | 29414 | 12.5 : 1/16 : 1/20:1 |

| 125D | 29416 | 12.5 : 1/16 : 1/20:1 |

| 140D | 29418 | 12.5 : 1/16 : 1/20:1 |

| 160D | 29420/29422 | 12.5 : 1/16 : 1/20:1 |

| 180D | 29422/29424 | 12.5 : 1/16 : 1/20:1 |

| 200D | 29426/29428 | 12.5 : 1/16 : 1/20:1 |