From the beginning, we have stated that Zeal Gears Pvt. Ltd is a company or production house that has gained expertise or rather set up a field for the helical gearboxes used in plastic and rubber machinery. But we have never restricted to only one type of product. Because we believe that the sky’s the limit.

PRODUCTS FOR INDUSTRIAL APPLICATION

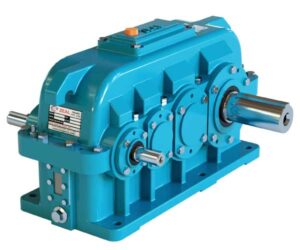

So, here we also manufacture parallel shaft helical gearboxes.

They are the ideal choice of helical gearboxes for material handling purposes. So, they are used in a wide range of industrial applications.

So, why choose zeal’s manufactured parallel helical gearboxes?

- They have horizontal / universal mounting designs.

- They are highly efficient.

- We construct it with hollow shafts on both sides.

- They have high power efficiency.

- They are available with both foot mounting and flanges for smooth mounting and installation.

- They are equipped with a multi-gear system to reduce the value of output speed.

- They can manage the high overhung load.

- The universal mounting feature that reduces void spaces created by some gearboxes.

Construction material or design

They are made with superior quality material which increases the longevity of the product and enhances its working efficiency.

- Cast with high graded iron.

- With an internal heating control system

- Equipped with a lubrication system

- Coated with heat resistant material.

- Lined with high-performance oil.

- Gear bearing cast in steel alloys.

Variants available

They are available in an array of variants to choose from. They are as follows:

- Foot-mounted

- Flange-mounted

- Shaft-mounted

- Output shafts with single extension and double extensions.

Features of the parallel shaft helical gearboxes

They come in a wide range of sizes and have distinguishable features which are as follows:

- They have high gear ratios.

- They come with gears that have either shaved profiles or ground profiles.

- They are accessorized with various bearings to offer high motor efficiency like output flanges, output shafts, torque arm etc.

- They have the capacity to run on the power of 0.12 kw to 45kw.

Applications of parallel shaft helical gearboxes

They can be used in various industrial applications like:

- Conveyors

- Agitators drives

We believe in providing optimal service to our customers that not only satisfies their requirement but also benefit them.

Our engineers are constantly working on the designs of these gearboxes to enhance the working efficiency of the devices and come up with advances in the machinery.

We believe that we can bring revolutionary changes in the industrial world of we bring the right technology in the market.

At Zeal Gears Pvt. Ltd our only aim is not only based on the commercialization of our product but instead we focus on coming up with designs with optimum results.

A start up that is constantly revolutionizing with interacting with customers and understanding their requirements.

FAQ for Parallel Shaft Helical Gearbox

What is a Parallel Shaft Helical Gearbox?

A Parallel Shaft Helical Gearbox is a type of gearbox where the input and output shafts are positioned parallel to each other. The gearbox uses helical gears, which have angled teeth to provide smooth and efficient power transmission between the shafts.

What are the typical applications of a Parallel Shaft Helical Gearbox?

These gearboxes are commonly used in various industrial applications, including conveyors, crushers, mixers, pumps, and material handling equipment. They are ideal for situations where space constraints require a compact design with parallel shaft alignment.

What are the advantages of using a Parallel Shaft Helical Gearbox?

The main advantages include high efficiency, compact design, low noise operation, and the ability to handle high torque loads. The helical gear design also reduces wear and tear, contributing to a longer lifespan.

How does a Parallel Shaft Helical Gearbox differ from other types of gearboxes?

Unlike right-angle gearboxes, where the input and output shafts are perpendicular, a parallel shaft gearbox has both shafts aligned parallel to each other. This design is more compact and can be more efficient for certain applications.

What materials are typically used in the construction of a Parallel Shaft Helical Gearbox?

The gears are usually made from high-strength alloy steel, while the housing is typically constructed from cast iron or steel. These materials provide durability and resistance to high loads and harsh operating conditions.

What factors should be considered when selecting a Parallel Shaft Helical Gearbox?

Key factors include the required torque and speed, the type of load, the mounting arrangement, and the environmental conditions (such as temperature and exposure to dust or chemicals). It’s also important to consider the gearbox’s efficiency and noise levels.

What are the maintenance requirements for a Parallel Shaft Helical Gearbox?

Regular maintenance includes checking and replacing the lubricant, inspecting gears and bearings for wear, ensuring proper alignment, and checking for any unusual noises or vibrations. Adhering to the manufacturer’s maintenance schedule is crucial for optimal performance and longevity.

Can a Parallel Shaft Helical Gearbox be customized?

Yes, many manufacturers offer customization options, such as different gear ratios, housing materials, and shaft configurations, to meet specific application requirements.

How does the helical gear design benefit the operation of the gearbox?

Helical gears have angled teeth, which engage more gradually compared to straight-cut gears. This design reduces noise, minimizes vibration, and allows for smoother power transmission, making the gearbox more efficient and durable.

What are the cooling options available for a Parallel Shaft Helical Gearbox?

Cooling options can include natural air cooling, forced air cooling, or water cooling, depending on the operational demands and the amount of heat generated during operation.

What are common issues that can arise with a Parallel Shaft Helical Gearbox?

Common issues include misalignment, excessive wear of gears or bearings, overheating, and lubricant leaks. Regular inspection and maintenance can help prevent these problems and ensure reliable operation.

How does the parallel shaft design influence the installation of the gearbox?

The parallel shaft design often results in a more compact and straightforward installation, particularly in applications where space is limited. Proper alignment during installation is essential to prevent premature wear and ensure smooth operation.

What is the typical lifespan of a Parallel Shaft Helical Gearbox?

With proper maintenance and appropriate application, these gearboxes can last many years. The exact lifespan depends on factors like the operating environment, load conditions, and maintenance practices.

Are there specific installation guidelines for a Parallel Shaft Helical Gearbox?

Yes, following the manufacturer’s installation guidelines is essential. These typically include ensuring accurate alignment, secure mounting, proper lubrication, and checking all connections and seals to prevent leaks and ensure efficient operation.