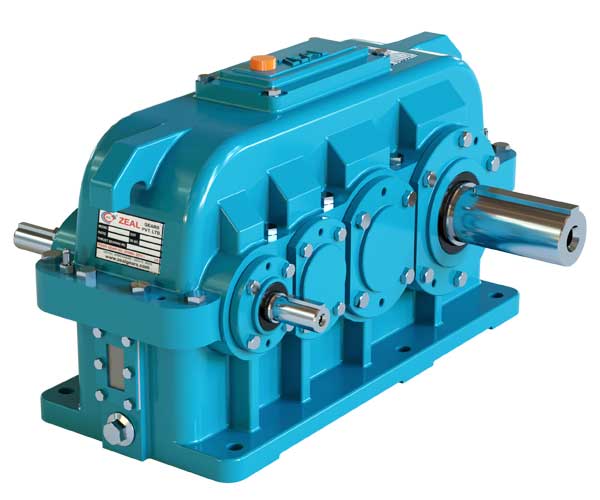

What is a Three-Stage Parallel Shaft Helical Gearbox?

A Three-Stage Parallel Shaft Helical Gearbox is a type of gearbox that uses three sets of helical gears to reduce speed and increase torque. The parallel design means that the input and output shafts are aligned parallel to each other, and the three stages allow for greater gear reduction ratios.

What are the typical applications of a Three-Stage Parallel Shaft Helical Gearbox?

These gearboxes are typically used in heavy-duty industrial applications such as conveyors, crushers, mixers, extruders, and large machinery where high torque and significant speed reduction are required.

What are the advantages of using a Three-Stage Parallel Shaft Helical Gearbox?

The main advantages include higher torque output, more significant speed reduction capabilities, and smoother, quieter operation due to the helical gear design. The three-stage configuration also allows for more flexibility in achieving desired gear ratios.

How does the three-stage design benefit the gearbox’s performance?

The three-stage design provides a higher reduction ratio, which means the gearbox can deliver more torque at lower speeds. This design also distributes the mechanical load over more gears, reducing wear and extending the gearbox’s operational life.

What materials are typically used in the construction of this gearbox?

The gears are usually made from high-strength alloy steel, while the housing is typically constructed from cast iron or steel. These materials are chosen for their durability, ability to handle high loads, and resistance to wear.

What factors should be considered when selecting a Three-Stage Parallel Shaft Helical Gearbox?

Key factors include the required torque and speed, the desired gear reduction ratio, the type of load, environmental conditions, and space constraints. It’s also important to consider the gearbox’s efficiency, noise levels, and maintenance requirements.

What are the maintenance requirements for this gearbox?

Regular maintenance involves checking and replacing lubricants, inspecting gears and bearings for wear, ensuring proper alignment, and monitoring for unusual noises or vibrations. Following the manufacturer’s maintenance schedule is crucial to ensure long-term reliability.

Can a Three-Stage Parallel Shaft Helical Gearbox be customized?

Yes, many manufacturers offer customization options such as different gear ratios, housing materials, and shaft configurations to meet specific application requirements. Custom cooling systems and lubrication options can also be provided based on the operational environment.

How does the helical gear design improve the performance of the gearbox?

Helical gears have angled teeth that engage gradually, resulting in smoother and quieter operation compared to straight-cut gears. This design reduces vibration, increases load-carrying capacity, and enhances the overall efficiency and lifespan of the gearbox.

What cooling options are available for this type of gearbox?

Cooling options may include natural air cooling, forced air cooling, or water cooling, depending on the operating conditions and heat generated during operation. Proper cooling is essential to maintain performance and prevent overheating.

What are common issues that can arise with a Three-Stage Parallel Shaft Helical Gearbox?

Common issues include misalignment, excessive wear on gears or bearings, overheating, and lubricant leaks. Regular inspections and maintenance can help prevent these issues and ensure reliable operation.

How does the parallel shaft design influence the installation of the gearbox?

The parallel shaft design generally results in a more compact and straightforward installation, especially in applications where space is limited. Proper alignment during installation is essential to prevent premature wear and ensure smooth operation.

What is the typical lifespan of a Three-Stage Parallel Shaft Helical Gearbox?

With proper maintenance and appropriate use, these gearboxes can have a lifespan of many years, often exceeding a decade, depending on the operating environment and load conditions.

What are the typical gear reduction ratios available for a Three-Stage Parallel Shaft Helical Gearbox?

The gear reduction ratios can vary, typically ranging from 15:1 to 500:1, depending on the specific design and application needs. Higher reduction ratios allow for greater torque output at lower speeds.

Are there specific installation guidelines for a Three-Stage Parallel Shaft Helical Gearbox?

Yes, installation should follow the manufacturer’s guidelines, including accurate alignment, secure mounting, proper lubrication, and checking all connections and seals. Ensuring that the gearbox is properly aligned with the driven equipment is crucial to prevent damage and ensure efficient operation.